35 years of Experience

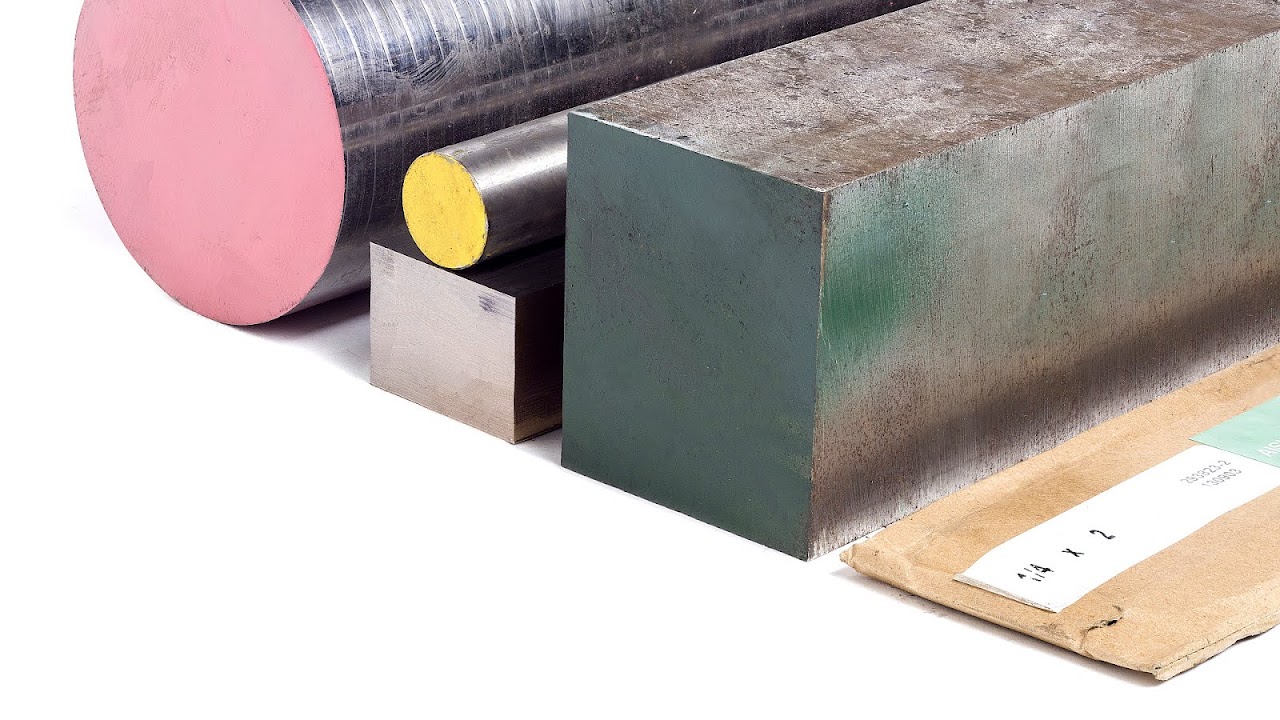

Cold work tool steels are essentially high carbon steels, which contain relatively low alloy additions of tungsten, manganese, chromium and molybdenum. These alloy additions increase hardenability, permitting oil quenching . These are relatively inexpensive steels, and their high carbon content produces adequate wear resistance for short run applications. It is used for all types of blanking and forming dies, gauges, collets, etc.

Hot work tool steels enable the hot-forming of work-pieces made of iron and non-ferrous metals as well as alloy derivatives at high temperatures. They are utilized in processes such as pressure die casting, extrusion and drop forging as well as in tube and glass manufacturing.

Tools made from hot-work tool steels are not only subject to constantly high temperatures when employed, but also to fluctuating thermic loads occurring where the tool surfaces come into contact with the materials to be processed.

Continuously growing activity in the area of the engineering plastics led to the necessity of developing new low-cost, high-performance plastic mold steels.

Precipitation hardening tool steels are being proposed for such an application, yielding improved mechanical properties and lower overall costs and lead-times.

Carbon steels contain only carbon as the principal alloying element. Other elements are present in small quantities, including those added for deoxidation. Silicon and manganese in cast carbon steels typically range from 0.25 to about 0.80% Si, and 0.50 to about 1.00% Mn.

Carbon steels can be classified according to their carbon content into three broad groups:

All inbound materials and outbound products are tested in our on-site analytical laboratory, ensuring that our solutions meet your requirements – guaranteed.

We pride ourselves on our ability to provide our partners with the flexibility and personalized service of a small distributor, while offering the professionalism and manufacturing capabilities of a large corporation.

Our partners are at the heart of everything we do; our mission is to meet your needs and exceed your expectations. We achieve this by creating a personal relationship with you and your company, ensure your products are delivered on time, and your product meet the exact chemical formula required.

We believe that as your Steel Trade partner we should add real value during every interaction, that’s why all of our staff members are experts in the Steel Trade industry.

1,2080

1,2379

1,2842

1,2344

1,2714

1,2365

1.2312

1.2316

1,2311

1,2738

1.2714

1,4140

C 45